27 Years of Industrial Painting Experience

Protech Contracting Services, Inc. offers industrial painting services throughout the Upper Midwest. With our skilled craftsman, 27 years experience, and access to modern coatings and coating systems we are able to complete small to large sized industrial painting projects in a wide range of industrial sectors. This includes work inside and outside your facility, all individually tailored to suit your budget, unique specifications and within your production schedules.

Maintenance, Renovation, and New Construction Painting and Coatings:

We work extensively with clients to perform painting and coating services that are long-lasting, durable and provides an extended lifetime through innovative materials and application techniques. We continually invest in the specialized training and new equipment necessary to perform a wide variety of industrial coating applications. The following list highlights some of the services we routinely provide:

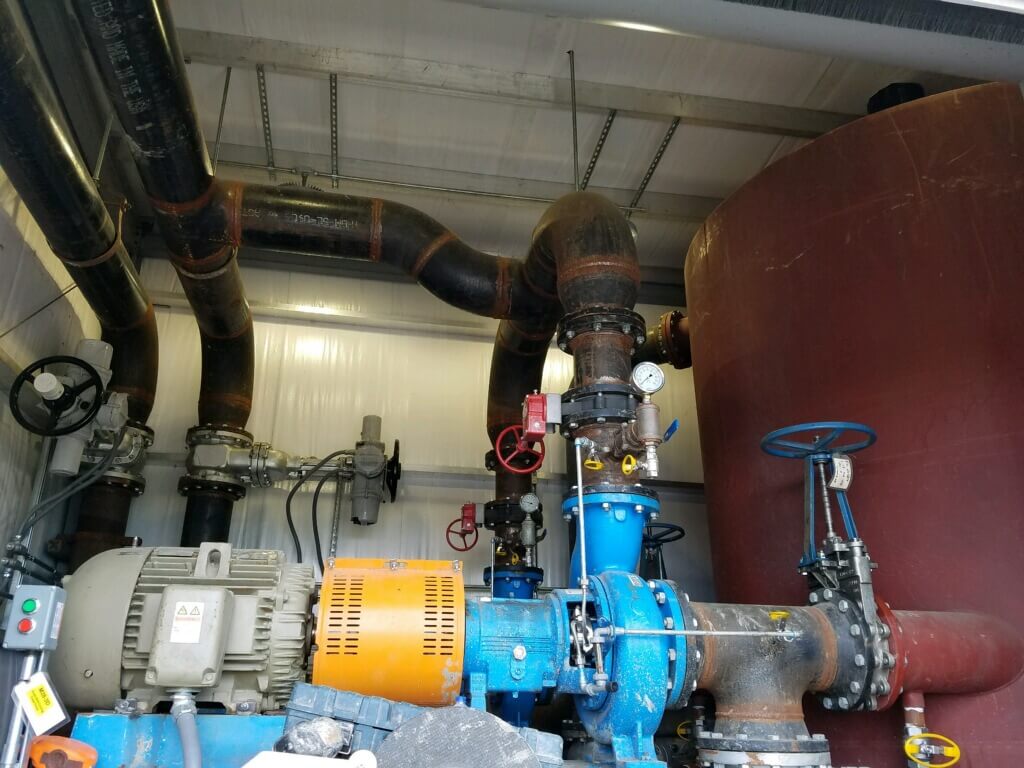

- Application of specialized corrosion protection systems.

- Conventional, airless and plural spray applications

- Tank linings interiors and tank exterior painting

- New construction industrial painting

- General maintenance painting

- Maintenance painting contracts

- Fireproofing

- Concrete repairs, restoration and protection

- Secondary Containment linings

- Chemical resistant paint, coatings and linings

- Wide variety of surface preparation methods including abrasive blasting, alternative blast media, high pressure water cleaning, diamond grinding, dustless surface preparation

- Industrial dust collection

- High temperature coating application

- Insulation coatings and work space temperature reduction

- Removal and disposal of old lead based coatings

- Wear resistant liners and surfacing

- Coatings for safety, identification and inventory management

Containment of in-process work areas:

Where required, Protech Contracting Services, Inc. can provide 100% encapsulation of the work area to ensure that our work has a minimal impact on your facility’s operations. Containment helps by controlling the dust, overspray and odor generated from painting operations. In addition, containing the work area also assures that the facility’s environment has a minimal impact on the successful painting application; by allowing coating operations to continue unabated from elements such as rain, wind, temperature, and exposure from plant processes. Ultimately, our goal is to perform and complete painting projects while enabling your facility to remain in operation with minimal maintenance disruption.

Surface preparation, painting and detailing creates a first impression that influences customers.

Protech routinely handles projects that require high production equipment and many personnel , often working in difficult aerial situations.